PEPIO F6/F12SC/F15

.jpg?width=300&name=seriapepiof6-f15%20(2).jpg)

- Description

- Applications

- Features

- Performance Specifications

- Technical Specifications

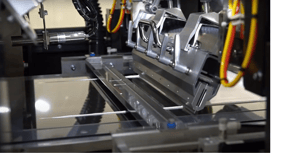

With the PEPIO F6, F12SC and PEPIO F15, you get advanced gravure offset printing technology designed to push the boundaries of precision and efficiency. Whether for semiconductor ball mounting, fine dot printing, or advanced packaging, these machines are built to handle the most demanding applications with ease.

Elevate your printing capabilities today with the PEPIO F6 / F12SC / F15 – the next generation of precision printing machines.

For more information or to request a demo, please communicate through contact us, Printed Electronics Products!

The PEPIO F6, PEPIO F12SC and PEPIO F15 are revolutionary semi-automatic gravure offset printing machines, designed to meet the demands of the most advanced printing technologies. Built for precision, versatility, and high-quality results, these machines are the perfect solution for industries that require high-resolution printing, such as semiconductors, electronics, and advanced packaging.

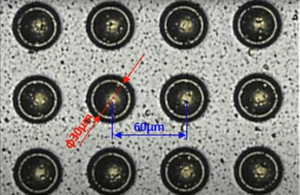

With features like line and space printing accuracy down to 5 µm, and the ability to print dots as small as 5 µm, the PEPIO series is engineered for cutting-edge performance.

- Semiconductor Manufacturing: Ideal for ball mounting and solder ball mounting in semiconductor packages.

- Electronics & Optics: High-precision printing for flexible circuits, displays, and other microelectronics.

- Packaging: Excellent for fine-line printing on packaging materials, such as labels and advanced packaging.

- Advanced Materials: Perfect for applications requiring fine dot printing (as small as 10 µm), such as flexible electronics and sensor technologies.

Key Features of the PEPIO F6 / PEPIO F12SC/ PEPIO F15

-

Advanced Printing Precision:

Min. Line Width: 5 µm

Min. Dot Diameter: φ5 µm

Printing Accuracy: Less than ± 5 µm (under 300×300 mm)

-

Exceptional Alignment:

Equipped with two CCD cameras for fine alignment, the PEPIO F6 and F15 provide precise registration, ensuring every print is aligned perfectly. -

High-Speed Printing:

Offset speed ranging from 2 mm/s to 200 mm/s, providing flexibility and speed for various production needs. -

Vacuum Fixing System:

Vacuum Fixing Method ensures stable and precise positioning of your workpieces during the printing process.

Vacuum Areas range from 150×150 mm (PEPIO F6) to 370×370 mm(PEPIO F15), allowing for larger workpieces and more diverse applications. -

Advanced Technology for Semiconductor Industry:

The PEPIO series is optimized for ball mounting and solder ball mountingapplications, making it perfect for the semiconductor industry, especially for the development of 30 µm ball mounting technology. -

Printing Direction & Speed Control:

Right→Left Printing Direction (viewed from the operator side)

Speed Control with Offset Speed and Table Speed during Coat/Printsettings down to 0.1 mm/s.

Innovative Special Features

-

Automatic Zero-Point Setting:

The PEPIO series automatically sets the zero-point for seamless operation, reducing manual adjustments and saving time. -

Anti-Static Bar:

Positioned near the rear side of the Blanket Cylinder, this feature helps eliminate static buildup during printing, improving print quality. -

Blanket Dryer Unit:

Includes an IR/Heat Circulation Dryer, ensuring the blanket maintains optimal conditions for high-quality prints. -

Ink Dispenser:

An integrated ink dispenser (pumping) system ensures a consistent and controlled ink flow for each print cycle. -

Blanket Cleaner:

Keeps the blanket clean for uninterrupted printing, maintaining consistent quality throughout production. -

Full Frame Cover:

Includes a full-frame cover (without HEPA filter) for enhanced cleanliness and protection during the printing process.

PEPIO F6:

- Max. Work Size: 160×160 mm

- Work Thickness: 0.05 mm – 2.0 mm

- Max. Glass Plate Size: 200×260 mm, thickness 5 mm

- Vacuum Area: 150×150 mm

- Vacuum Hole Diameter / Pitch: φ0.8 mm / 10 mm

- Machine Dimensions: 1859×1404×2047 mm

- Machine Weight: Approx. 1600 kg

PEPIO F15:

- Max. Work Size: 380×380 mm

- Work Thickness: 0.05 mm – 2.0 mm

- Max. Glass Plate Size: 420×500 mm, thickness 5 mm

- Vacuum Area: 370×370 mm

- Vacuum Hole Diameter / Pitch: φ0.8 mm / 10 mm

- Machine Dimensions: 2910×1230×1805 mm

- Machine Weight: Approx. 3500 kg

| PEPIO F6 | PEPIO F15 | |

| Max. Work Size (TD×MD) | (TD)160×(MD)160 mm | (TD)380×(MD)380 mm |

| Work Thickness | 0.05〜2.0 mm | |

| Max. glass plate size (TD×MD) | (TD)200×(MD)260 t=5 mm | (TD)420×(MD)500 t=5 mm |

| Printing (offset / process) Direction | Right→Left(sight from Operation Side) | |

| Worktable | With Alignment Function | |

| Work Fixing Method | Fix by vacuum pump | |

| Vacuum Area (TD×MD) | (TD)150×(MD)150 mm | (TD)370×(MD)370 mm |

| Vacuum Hole Diameter / Pitch | φ0.8 mm /10 mm | |

| Offset speed | 2〜200 mm/s (Parameter Setting) | |

| Alignment Adjustment Camera | CCD Camera 2 units | |

| Camera view range | Approx. 6×6 mm | |

| Work Distance | Approx. 170 mm | |

| Plate (Screen) Table Fixing Method | Fix by vacuum | |

| Vacuum Area (TD×MD) | (TD)190×(MD)250 mm | (TD)410×(MD)490 mm |

| Vacuum Hole Diameter / Pitch | φ2.0 mm /10 mm | |

| Offset speed | 2.0〜200.0 mm/s (Parameter Setting) 0.1 mm/s (unit) | |

| Table Speed during Coat / Print | 2.0〜200.0 mm/s (Parameter Setting) 0.1 mm/s (unit) | |

| Blanket Cylinder Ref. diameter | φ190 mm | |

| Blanket treatment | t=2.0〜3.0 mm (Including Under Blanket) | t=0.5〜3.0 mm (Including Under Blanket) |

| Printing pressure (Cylinder pos. setting) | 0.000〜0.250µm (Parameter Setting) | |

| Rotation Speed Ratio (to work / plate) | -0.20 〜 +0.20% (Parameter Setting) | -0.500 〜 +0.500% (Parameter Setting) |

| Machine Dimensions(W×D×H) | (W)1859×(D)1404×(H)2047 mm | (W)2910×(D)1230×(H)1805 mm |

| Machine Weight | Approx. 1600 kg | Approx. 3500 kg |

| Power Supply | 3-Phase 200V 50/60Hz 6.9kW | |

| Air Supply | 30Litter/min 0.5MPa | |

| [TD: 90° for printing direction / MD: Printing direction] | ||

| Auto 0 Point Setting | : Automatic |

| Anti-static bar | : Blanket Cylinder near rear side of printing |

| Dryer unit for blanket | : IR /Heat circulation |

| Ink dispenser | : Ink dispenser (Pumping) |

| Blanket cleaner | |

| Full Frame Cover | : Without HEPA Filter |

.jpg?width=300&name=seriasvm6151ip%20(1).jpg)

.jpg?width=300&name=seriaryurone35sz%20(1).jpg)