SVM-6151IP

Experience the Next Generation of Coating Technology

Unlock advanced coating precision with the SVM-6151IP, an innovative vacuum coating system designed for high-performance applications across various industries. Equipped with cutting-edge technology, this machine ensures flawless coatings, precise alignment, and versatility, making it the ideal solution for complex and high-quality coating, printing, and semiconductor packaging needs.

The SVM-6151IP Semi-Automatic Vacuum Coating Machine with CCD Camera is a top-tier choice for any business seeking enhanced coating quality, precision, and efficiency. Whether you're producing complex semiconductor packages, intricate electronic components, or high-performance optical coatings, this machine ensures that your production processes are efficient, precise, and of the highest quality.

Elevate your production line today with the SVM-6151IP – your ultimate solution for precision coating, printing, and semiconductor packaging needs.

.jpg?width=300&name=seriasvm6151ip%20(1).jpg)

- Technology

- Applications

- Key Features

- Performance Specifications

- Optional Features

- Industries That Benefit from the SVM-6151IP

Advanced Technology for Better Results

Dual CCD Camera System:

The two integrated CCD cameras provide real-time monitoring and precise alignment, ensuring that every print and coating is accurate and of the highest quality.

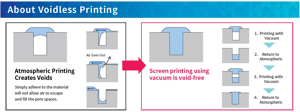

Vacuum Pump Technology

With a powerful vacuum pump system rated at 33.2 kW, the machine delivers superior coating results. The vacuum system ensures bubble-free application, critical for high-precision industries.

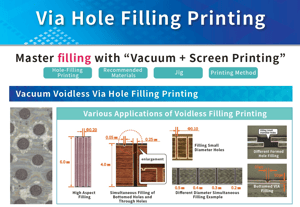

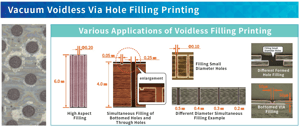

Filling Printing Technology for Semiconductors:

Perfect for semiconductor package manufacturing and interposer filling, the machine utilizes advanced Filling Printing Technology to ensure accurate material placement in the microelectronics industry. This technology is key for achieving the tight tolerances required in semiconductor packaging.

The SVM-6151IP offers a broad range of applications, including:

Semiconductor Package Manufacturing:

Ideal for interposer filling and other semiconductor applications, ensuring precise material deposition for reliable package performance.

Electronics Manufacturing:

Apply protective coatings to PCBs, sensors, and other delicate components, ensuring long-lasting protection and improved performance.

Automotive Industry:

Use for decorative coatings, hole plugging, and protective layers on automotive parts, enhancing both aesthetics and durability.

Packaging Industry:

Perfect for printing and coating packaging materials such as bottles, cans, and containers with precision.

Optical Coatings:

Apply thin, even coatings to optical lenses, light guides, and other components used in optics and displays.

-

Auto Alignment System: The machine is equipped with an advanced auto alignment system that ensures perfect alignment with every application, reducing human error and increasing throughput.

-

Multi-Function Capabilities: Whether you need to apply coatings for high aspect ratio plugging, selective printing, semiconductor packaging, or other specialized applications, the SVM-6151IP is built to handle it all. Its flexibility supports a wide range of industries, including electronics, automotive, semiconductors, and medical devices.

-

Filling Printing Technology: With cutting-edge Filling Printing Technology, the machine is well-suited for semiconductor package manufacturing and interposer filling, offering highly precise deposition of materials in microelectronics, ensuring uniformity and reliability in your semiconductor products.

-

High-Precision Coating: Achieve bubble-free, uniform coatings with vacuum pressure ranging from 100–12,000 Pa. This feature is essential for applications where coating consistency and quality are paramount, like electronics and optical components.

-

Fine Alignment and Plugging: The machine is especially effective for selective alignment and plugging applications, providing highly accurate positioning for fine coatings and precise hole plugging, particularly in high aspect ratio workpieces.

Wide Work Size Range: Handles workpieces with sizes from 200×200 mm to 610×510 mm, offering great flexibility for various production needs.

Customizable Speed and Pressure Settings: The SVM-6151IP allows you to adjust speed (10.0 to 300.0 mm/sec) and pressure (100-800 N) to optimize the coating process for different materials and production speeds.

Robust Design: With a frame size of 1000×1100 mm and a machine weight of approximately 3500 kg, the SVM-6151IP is designed for stability, ensuring consistent performance even in high-demand production environments

-

Roller Head: The SERIA original roller head (patented) is ideal for high aspect ratio hole plugging applications, ensuring maximum efficiency and precision.

-

Work Clamp Plate: Fix your workpieces securely onto the jig plate with the work clamp feature, ensuring stability throughout the coating process for enhanced accuracy.

-

Screen-less Option: The screen-less design allows for extra space for ink standby and supply, improving operational efficiency by reducing downtime and maintaining a smooth workflow.

- Semiconductor Manufacturing (Package manufacturing, Interposer filling)

- Electronics Manufacturing

- Automotive

- Packaging

- Optical and Display

- Medical Devices

- Consumer Electronics

- Aerospace

- Solar Technology

- Textile Coatings

Why Choose the SVM-6151IP?

Technical Specifications

| Max. Work Size (W×D) | (W)610×(D)510㎜ |

| Min. Work Size (W×D) | (W)200×(D)200㎜ |

| Work Thickness | t0.4-5.0㎜ |

| Frame Size (W×D) | (W)1000×(D)1100㎜ t25-30㎜ |

| SQ Length | Max. 650㎜ |

| SQ Pressure | 100-800N Parameter Setting |

| SQ Speed | 10.0-300.0㎜/sec Parameter Setting |

| SQ Stroke | 750㎜ |

| Print Table Size (W×D) | (W)730×(D)730㎜ |

| CCD Camera | 2 Camera |

| Vacuum Pressure Level | 100-12000Pa (New) Parameter Setting |

| Machine Dimensions | (W)2960×(D)2060×(H)2100㎜ (without Vacuum Pump) |

| Machine Weight | (Approx.) 3500 kg |

| Power Supply | Body: AC200V 3phase 50/60Hz 2.1kW Vacuum Pumps: AC200V 3phase 50/60Hz 33.2kW |

| Air Supply | Drive: 100ℓ/min 0.5MPa Purge: 100ℓ/min 0.5MPa |

| Cooling Water | Vacuum Pump: 6-9ℓ/min 0.28-0.5MPa Max 30°C |

| Roller head | SERIA original roller head (patented) has elective for hole plugging |

| Work clamp | Work clamp plate is for work fixing onto jig plate / others |

| Screen less | Makes space for ink standby / supply |

.jpg?width=300&name=seriasvm6151ip%20(1).jpg)

.jpg?width=300&name=seriaryurone35sz%20(1).jpg)