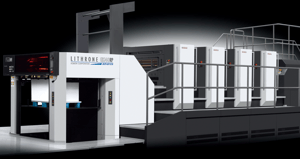

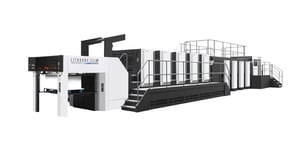

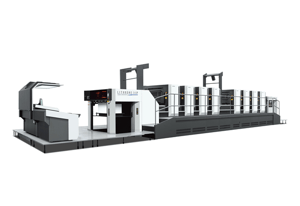

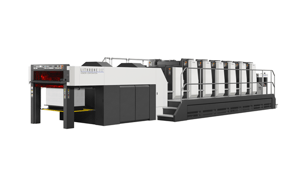

LITHRONE GX40RP

advance EX EDITION

AN EXCLUSIVE 41", DEDICATED, TWO-SIDED PRINT SOLUTION

THE PERFECT DEDICATED, TWO-SIDED PRINTING PRINTING PRESS

Why Lithrone GX40RP Advance EX Edition?

Features

-

Komorimatic Dampener: Komori's unique dampener design provides the most consistent and uniform water film control in the industry.

-

SmartFlow Inking: An updated ink train designed to respond faster during makeready for fast, low waste make-readies.

-

Print Characteristics: Superb registration and low dot gain make high quality printing consistent and repeatable.

-

KHS-AI: Komori's masterful control system uses AI learning to optimize makeready functions. A Komori exclusive for nearly two decades.

-

Smart Sequence: Komori's terminology for the capability to run a series of print jobs back to back in automated sequence.

-

On-Press Automation: Asynchronous auto plate changing, parallel process controls, multiple pre-inking functions and built in maintenance assist programs ease the skillset of the operator.

-

EX Edition Upgrade: All Komori advance presses now include our latest EX Edition technology, reducing power while increasing process control and productivity.

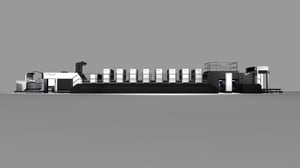

Specifications

| Number of colors | 2-12 |

| Maximum print speed | 18,000 sph |

| Maximum sheet size | 29.5" x 41.3" |

| Minimum sheet size | 14" x 20" |

| Thin sheet application range | 0.0016" - 0.020" |

| Thick sheet application range | 0.008" - 32pt |

| Feeder Pile Height | 1,850 (72.8") |

| Delivery Pile Height | 1,450 (57.1") |

Product Brochures